Karakteristike naše Laserski stroj od 1000 W

1.Stabilnost i pouzdanost sustava svjetlosnih staza i upravljačkog sustava

2.Iportirani originalni vlaknasti laseri, visoke i stabilne funkcije, životni vijek je preko 100000 sati

3.Više kvaliteta i učinkovitost rezanja, brzina rezanja je do 80 m / min, s izgledom i lijepim reznim rubom

4.Njemački visokoučinkoviti reduktor, zupčanik i stalak; japanska vodilica i kuglični vijak.

Primjenjiva industrija i materijali stroj za lasersko rezanje vlakana

stroj za lasersko rezanje vlakana primjena:

rezanje metala, proizvodnja električnih prekidača, zrakoplovstvo, prehrambeni strojevi, tekstilni strojevi, inženjerski strojevi, proizvodnja lokomotiva, strojevi za poljoprivredu i šumarstvo, proizvodnja dizala, specijalna vozila, kućanski aparati, alati, obrada, IT proizvodnja, strojevi za naftu, strojevi za hranu, dijamantni alati , zavarivanje, oprema za zavarivanje, metalni materijali, reklama za dekoraciju, laserska površinska obrada stranih usluga obrade, kao što su sve vrste industrije prerade strojeva.

Naše stroj za lasersko rezanje vlakanaMaterijali za prijavu:

Profesionalni se koristi za rezanje tankog lima, u raznim visokokvalitetnim rezanjem limova od ugljičnog čelika od 0,5 -3 mm, također se može rezati ploča od nehrđajućeg čelika, ploča od aluminijske legure, pocinčani lim, elektrolitička ploča, silikonski čelik, legura titana, aluminij cink ploča i drugi metal.

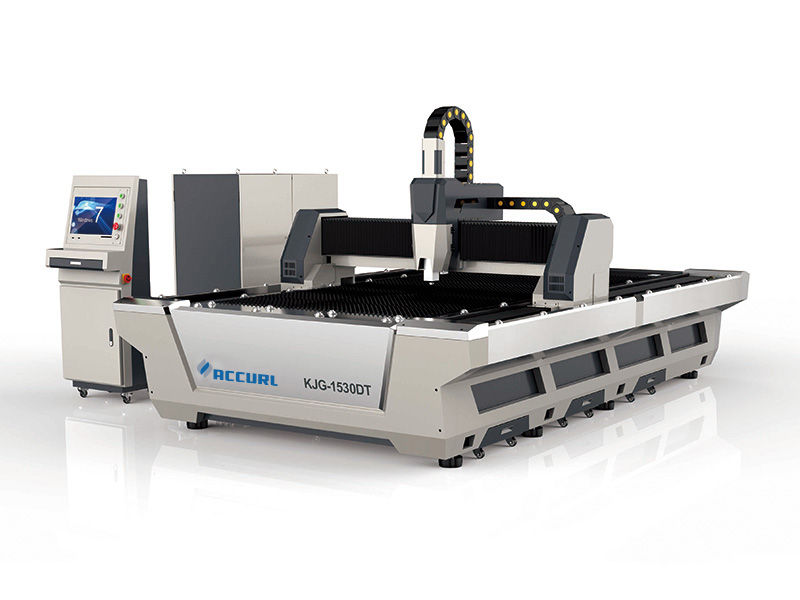

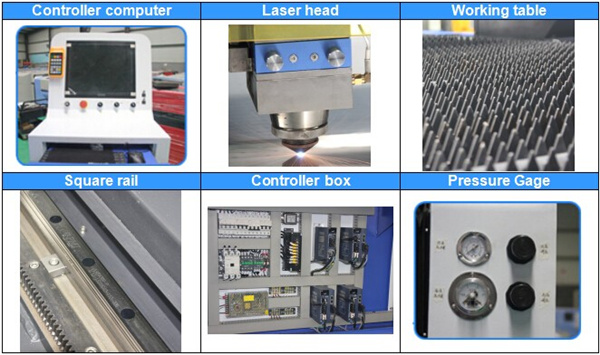

Glavne slike stroja 1kw stroj za lasersko rezanje

Brzi detalji

Primjena: lasersko rezanje

Stanje: Novo

Tip lasera: Fiber laser

Primjenjivi materijal: Metal

Debljina rezanja: 0-20 mm

Površina rezanja: 1300 * 2500mm

Brzina rezanja: 25m / min

CNC ili ne: Da

Način hlađenja: vodeno hlađenje

Kontrolni softver: bechoff ( Cypcut )

Podržani grafički format: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certifikacija: CE, ISO, SGS

Dostavna usluga: Inženjeri dostupni za servisiranje strojeva u inozemstvu

Model: laser od 1000 vati

Materijali za rezanje: nehrđajući čelik ugljični čelik itd (stroj za lasersko rezanje metala)

Tip generatora laserskog vlakna: poznati brend Raycus (proizvedeno u Kini)

Glava za lasersko rezanje vlakana: Lasermech (iz SAD-a)

Motori i drajveri: 1500W Fuji servo motor proizveden u Japanu

Min. Širina linije: ±0,02 mm

Radni vijek modula vlakana: Više od 100 000 sati

Jamstveno vrijeme: Cijeli stroj 3 godine (fib

Parametar našeg Stroj za lasersko rezanje vlakana

| Model stroja | 2500 * 1300mm |

| Laserska snaga | 300W/500W/1000W/3000W |

| Tip generatora laserskog vlakna | Poznati brend Raycus (Made in China) |

| Laserska valna duljina | 1064nm |

Kvaliteta laserskog snopa | <0.373mrad |

| Radni stol | pilasti |

| Vlakna glava za rezanje laserom | Lasermech (iz SAD-a) |

| Fokusna leća | Lasermech proizveden u SAD-u |

| Radni vijek modula vlakana | Više od 100000 sati |

| Motori i driveri | 1500W Fuji servo motor proizveden u Japanu |

| Redukcija | 3 kompleta iz Njemačke |

| Tračnice vodiča | Brend PMI visoke preciznosti iz Tajvana |

| Prijenosni sustav | Dvostruki tip zupčanika i zupčanika |

| Rack sustav | Njemačka stalak |

| Lančani sustav | Igus proizveden u Njemačkoj |

| Hladnjak vode | Marka TEYU(S&A), CW6000 |

| Kontrolni sustav | Profesionalni laserski upravljački sustav - Cypcut

|

| Vrsta položaja | Crvena točka |

| Debljina rezanja | ≤3 mm (nehrđajući čelik) ≤6 mm (ugljični čelik) |

| Maks. Brzina rada u praznom hodu | 1400 mm/s |

| Brzina rezanja | 300mm / s |

| Točnost položaja | ±0,05 mm/m |

| Brzina položaja | 20 m/min |

| Min. Širina linije | ± 0,02 |

| Potrošnja energije | ≤12KW |

| Nosite težinu | 700KG |

| napon | 380V/50HZ,3PH |

| Pomoćni plin za rezanje | Kisik, dušik, zrak |

| Kompatibilni softver | Autocad, Coreldraw itd |

| Grafički format | Nc |

| Način rada | PC kontrola |

| Ukupna ocjena zaštite od napajanja | IP54 |

| Težina stroja | Oko 4000 kg |

| Veličina stroja | 4800*2600*1800 mm |

| Vrijeme garancije | Cijeli stroj 3 godine (modul vlakana 2 godine) |

Kontrola kvalitete lasera od 1000W

Kvaliteta je naše najiskrenije poštovanje prema svim našim kupcima i najvažniji je čimbenik za održavanje dugoročne poslovne veze s nama.

Uvijek više pažnje posvećujemo kvaliteti stroja za lasersko rezanje. Standardni sustav kontrole kvalitete i tim odgovorni su za osiguranje kvalitete proizvoda u svakom procesu s različitim instrumentima kao što su laserski interferometar i laserski mjerač snage.

U procesu mehaničkog sastavljanja koriste se laserski interferometar, laserski kolimator, indikator brojčanika i mramorna ploča; U procesu sastavljanja lasera koriste se mjerač snage lasera i optički mikroskop.