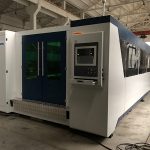

Pregled

Oprema za lasersko rezanje researched and developed by our company is constituted with the high quality fiber

laser generator, high precision double drive gear rack transmission and advanced automation control system,

which has reached a new height of laser cutting and high precision mechanical NC technology. With realizing

the perfect combination of high speed, high precision, high efficiency and low cost, it can be the best choice

for bulk metal materials cutting job.

Specifikacija

| Laserska snaga | 2000W (optional500W/700W/1000W/3000W) |

Laser Wave Length | 1070nm |

| Radno područje | 1500x3000mm |

| Maximum Cutting Thickness | 16 mm |

| Maksimalna brzina rada u praznom hodu | 80m / min |

| Maximum Idle Running acceleration | 0,8 g |

| X.Y axis Location Accuracy | ≤±0.03mm |

| X.Y axis Repeat Location Accuracy | ≤±0.02mm |

| Laser Device | Raycus/IPG |

| Transmission System | Double drive gear rack |

| Kontrolni sustav | BOCHU/Germany PA8000 |

| Način vožnje | Japan Yaskawa motor (YASKAWA) |

| Napajanje | Three-phase 50Hz/60Hz AC380V |

| Bruto snaga | 18000W |

| Podržani grafički format | BMP, DST, GIF, TGA, AI, PLT, DXF, LAS,etc. |

| Kompatibilni softver | CorelDraw AutoCAD Photoshop |

| Type Of Cooling | Vodeno hlađenje |

Construction Features

1. Laser

Adopting the world’s top fiber laser, stable performance, high efficiency and low cost.

2. Mechanical structure

With double drive closed-loop structure displacement, Y direction has a strong driving force and high speed,

which can give full play to the high speed characteristics of fiber laser.

After two times of aging treatment, the structure of bed body is strengthened to ensure the stability and precision

of bed body for a long time.

3. Control system

By using open CNC system provided by the top suppliers and integrating the company experience in laser industry

for many years, the man-machine interface is so simple and more convenient to operate.

4. Follow-up cutting head

By using the follow-up cutting head of international famous brand, the laser is always in the focus position, can

ensure the cutting effect.

5. Metal nesting software

The optimized software algorithm can save the material to the maximum extent. Integrated a variety of specialty

metal cutting technology such as common edge,bridge and micro connection,the difficulty of operation is reduced,

so that improves the material management function, make full use of waste materials and meet the management

needs.

6. Auxiliary air blowing system

System combines high and low voltage conversion gas path and three gas source structure composed of high

pressure air, nitrogen and oxygen, so customers can select the auxiliary gas according to the processing quality

requirements and cost.

7. Lubrication system

The whole machine is equipped with lubrication system, which reduces the wear of moving parts and ensures the

movement speed of the whole machine.

8. Editing system

The software supports the input and output of the general CAD format file (PLT, DXF, DST, AI, BMP, etc), as well

as graphics editor (zoom, rotate, array, etc)function.

Prednost

1. The laser cutting process is controlled by the computer, the cutting precision and the artistic effect can be guaranteed

due to the stable power and uniform cutting seam.

2. Import transmission parts and servo motor, high dynamic movement performance and high cutting precision.

3. Compared with the CO2 laser cutting machine, the photoelectric conversion efficiency of the fiber laser cutting machine

is three times, as high as 25%—30%.

4. Can be compatible with AutoCAD, CorelDRAW, Photoshop and other software output, support HML, DXF, PLT, DST,

BMP, WXZ and other image formats, can directly use TF, SHX characters.

5. Cutting workbench and laser power can be configured according to the needs of users,which can meet the needs of

different users on the objects processing, so achieve the purpose of saving and giving full play to the performance

of the equipment.

Industries

Kitchen cabinets, sheet metal processing, advertising lighting, food machinery, automobile

manufacturing, environmental protection equipment, elevator manufacturing, agricultural

machinery, signs production, medical equipment, wind machine, hardware tools, arts and

crafts etc.

Suitable

materijali

Stainless steel, carbon steel, galvanized plate, various alloy, organic glass, architectural

models, rubber, wood products, glass panel, billboards, crystal characters, furniture

and other toys etc.

Predprodajna usluga

Whether you are a dealer or an end user, as long as you are interested in our products, once you contact us, we will

arrange a particular professional sales representative at your service to help you have a deep understanding of us

and our products or answer your questions on marking machines and applications.

Production Process

Machine will be carefully test and adjust before package. We run the machine for a few days, and then use customer's

materials for test, most of the parameters will be set. After making sure machine is the best performance, so customer

can use the machine directly without adjustment.

On-Time Delivery

After you confirm the order, we will figure out the delivery date according to the model and production schedule. Once

deals were settled down, we will confirm you the exact lead time and shipping time.

Servis nakon prodaje

1.Installation Service

our technicians will provide on-site service. According to the specific circumstances, we will arrange technicians go

abroad to install the machine. (Customers only need to pay the airfare and hotel )

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your

technician to our company to learn how to operate machines.

3.Quality Guarantee

We guarantee the quality of machine, and the whole machine warranty for one year.(quick-wear parts not included)

Once malfunction occurs,We guarantee we will give you a clear reply within 24 hours. Customer service staff will assist

and guide you to analyze the malfunction in order to locate the cause and solve the problem as soon as possible.